- COOLING TOWERS:

In general, the process cooling water has a temperature between 40 and 60°C. The water is pumped to the upper part of the cooling tower and falls down passing numerous wooden or plastic partitions that disperse the water into small droplets.

The droplets pass forced ventilation that flows from the bottom to the top. During this process the temperature drops around 10 to 20°C.

Most surface waters contain traces of Legionella, of which the specific Legionella Pneumophila bacteria can cause severe lung infection. They are most harmful when vaporized and inhaled trough the wet air.

These bacteria are very difficult to combat with chemicals.

Investigation (WHO-1999) showed that about 10% of the legionella clusters can be attributed to cooling towers.

Important factors for the legionella growth are :

- type of cooling tower

- temperature of the water (highest risc between 20 and 50°C)

- water flow (whereby low flow and periods of standstill are most dangerous)

- the presence of a surface with biofilm and sediments (nutrients)

The first three factors can be dealth with trough design.

The complete elimination of biofilm in the cooling tower and pipe systems can be done trough ultrasone technology.

The Aquasonic device can be installed afloat in the collection reservoir.

The Biosonic device can be placed in the cooling water pipes.

The ultrasound signal  penetrates the smallest hair-and fatigue cracks where chemicals (that only reduce the surface tension ) cannot reach.

penetrates the smallest hair-and fatigue cracks where chemicals (that only reduce the surface tension ) cannot reach.

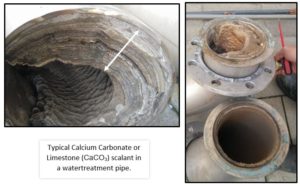

- LIMESTONE IN PIPING SYSTEMS

Depending on the processes and type of water used, limescaling can be a continuous problem in factories.

Ultrasound can both remove (over time) and prevent limestone formation.

- STORAGE RESERVOIRS:

Open water reservoirs have all conditions (sun,heat,water,air,nutrients) and are an ideal environment for the growth of algae and biofilm.

Microscopic spores are continuously introduced trough rain and wind causing uncontrolled growth of all kinds of organic matter.

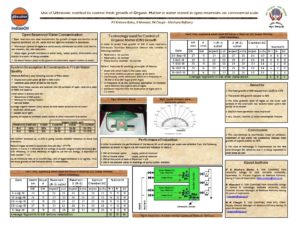

An Ultrasonic Biomass Reduction Device was installed in the Mathura Refinery (Indian Oil).

Quote of the conclusion after the test:

- This non-chemical and eco-friendly mode of ultrasonic treatment of raw water has successfully reduced fresh growth of organic matter by 40%.

- This kind of technology is implemented for the first time amongst IDC refineries and it is being replicated in other areas as well.”