The formation of calcium salts and its compounds (like beer stone or Calcium Oxalate – C2CaO4) is a problem in breweries, beer dispensers and storage tanks.

This organic compound precipitate on the walls of (aging) tanks, coolers, piping and kegs. When the scaling becomes visible it is already very difficult to remove.

Beer stone is formed from the combination of grains, water (which includes calcium and magnesium), alkaline cleaning agents and the reaction with amino acids (in the form of proteins).

Micro-organisms such as anaerobic bacteria can grow inside the porous beer stone and micro-cracks in the surface and are very difficult to remove.

This leaves an unsanitary surface that, in the best case, decreases the lifetime of the beer and causes smelling. In the worst case, the organisms can waste the whole batch and can even cause health issues.

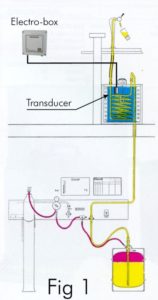

Fig1; the transducer is about 10mm immersed into the cooling water reservoir of the dispensing installation.

The transducer is simply plugged-in into the control box.

The control box is connected to the mains (110V/230V)

The Brewsonic can remove biofilm (and thus the related beer stone) from the surface and pores of tank and pipe and prevent recurrence when left in continuous operation.

Old installations will clean themselves after time (allow for ample flushing to remove scaling and deposits).

New installations will obviously remain clean.

The organoleptic properties (like color, odor, texture or taste) will not be affected!

Presentation (RU) : biertanks russisch Brewsonic