Air, smoke and gas tightness are important in relation to:

- the conservation of fuel and energy (in buildings and temperature controlled spaces)

- optimalisation of the comfort (controlling the flow in passive houses, temperature and acoustic insulation,..)

- improving fire safety (smoke leak prevention)

- pollution prevention (ie leaking tanks, spreading of noxious gases,..)

- eliminating smell disturbance in offices (near processing plants, in refineries,..)

Upon request we perform customized non-destructive and reliable ultrasound measurements for:

1- Land based applications:

- tightness testing of (fuel)tanks:above ground tanks (with visualisation of the leak location and intensity)

- underground tanks (no visualisation possible, but certainty of no leakage)

- air tightness or permeability testing of buildings and residential houses:

- on prefab structures, as a quality control before leaving the factory

- as a building prescan, to resolve leaks at an early stage (while they can still be rectified in an economical way)to measure compliance with fire security (smoke

- leak detection on pipes and tanks containing pressurized air or gasses

- water-wind-and noise testing in the automotive sector…

2- Off-shore structures and ship applications:

- general tank tightness testing

- testing of water and weather tightness of marine structures and equipment like:

- watertight doors and bulkheads

- access hatches and bulk carrier hatch covers (to avoid claims and damage to cargo)

- portholes and windows

- electric cable and pipe penetrations,…

- Insulated immersion suits

- leak detection on pipes and tanks containing pressurized air or gasses

- thermal and acoustic tightness testing on pleasure boats and commercial yachts

- …

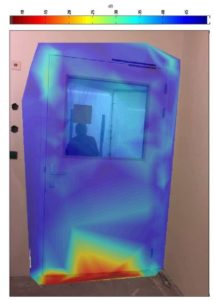

Were possible, our reports contain a still of the visualisation of location and the extend of the detected leak(s), similar to the IR (thermal) detection method.

Remarks:

-The used ultrasound methode is a convenient alternative to the more cumbersome and time consuming IR techniques, blowerdoor testing, water-or smoke testing, hose testing,…

-Testing on marine structures is done with type approved equipment. Protocols used are accepted by several P&I clubs and IACS members. Call us for info.

Info on Passive Houses : Passive House Institute

Hatchcover testing , Risk Focus

Pictures: courtesy of ypemedia and Ultragraphyx®