Ultrasound technology and catalysts do not add oxygen or increase the oxygen level (DO), but they split the existing larger bubbles (≈1-4mm) into to very fine micro/nano bubbles.

This has the following unique effects:

- increase the capacity of water to contain oxygen (higher gas transfer capability)

- keeps the DO longer stable in the water

- enlarges the surface of the bubbles whereby they become more bio available

- reduce the surface tension of the bubble and interface with the water

- optimize nutrient uptake and general plant health

- has a cleaning effect along surfaces

- faster decomposition of organic material

- accelerate the increase in DO when using H2O2 or another O₂ injection method.

The ultrasound has an additional effect of creating an environment that reduces the proliferation of free-floating (planktonic) microbiology.

To add oxygen you have to agitate the water or inject it trough a porous stone or bubble generator.

By selecting a suitable technology, you look for a simple system with low power consumption.

Nanobubbles are classified as bubbles smaller than 200 nm

Detection methods include DLS, NTA, zeta potential measurement, cryo-TEM, and ultrasound techniques. ISO and ASTM are actively developing standards to standardize the field of nanobubbles.

Size:

- Nanobubbles are generally classified as having a diameter of less than 200 nanometers (nm), with most being around 100 nm or smaller.

- They are significantly smaller than microbubbles (1–100 micrometers) and have unique physical properties.

Properties:

- High Surface Area: Despite their small size, they provide a large surface area for gas transfer.

- Long Stability: Unlike larger bubbles, nanobubbles can remain stable in water for days to weeks due to their near-zero buoyancy and high internal pressure.

- Negative Surface Charge: Nanobubbles often have a negatively charged surface (zeta potential), which contributes to their stability and interaction with particles.

- High Gas Transfer Efficiency: Due to their small size and surface properties, they dissolve gases efficiently into liquids.

It is a technology developed by applying the shear resistance relationship between the interface of the object and the adjacent area. When gas(ex. oxygen) is splitted into nanosize by the shear force generated at the interface of the object, dissolved gas is increased. Nano-sized bubble(gas) exists in water for a long time without degassing, and dissolved gas is maintained high for a long time.

The Newman Tech’s nanobubble generation technology is different from existing technology. It is the principle that the shear force is applied to the flowing gas-liquid mixture and it is split into bubbles. Specifically, when the gas-liquid mixture moves in contact with a specific surface, a velocity gradient occurs due to the boundary layer effect, and the gas-liquid mixture is continuously split to a nano bubble.

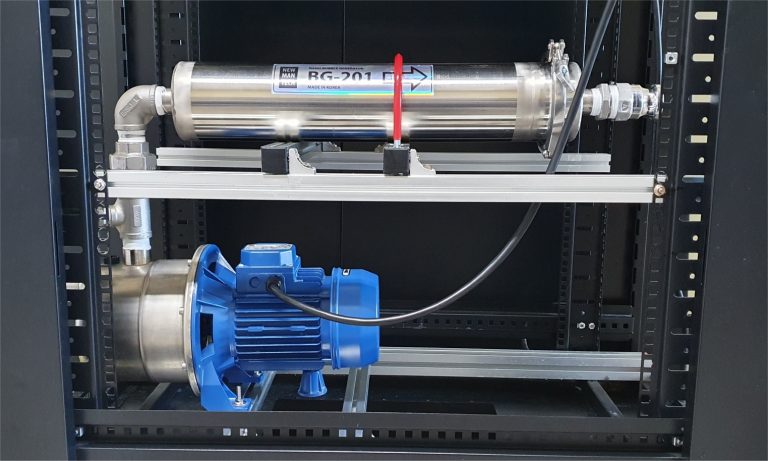

The 2025 version of the N2BG consists of one pump and one bubble generator. The configuration is simpler than

the previous N2BG, making installation and maintenance easier. The pressure of the pump is 4kgf/cm^2, and

this pressure is the energy for making shear forces, and the higher the pressure, the smaller the bubble. Gas is

injected in front of the pump and in an amount that will not cause cavitation in the pump. The 2025 version of

the N2BG has no blockage caused by solids. So It can be applied to water with high solids concentration such as

fish farms and wastewater treatment plants. And it is possible to install the bubble generator in parallel, so the

capacity can be increased to 2,000m^3/day or more.