Biofilm formation in water installations, such as cooling towers, pipelines, and heating systems, represents a significant challenge in industrial and residential settings.

A biofilm is a complex aggregation of microorganisms, including bacteria, algae, fungi, and protozoa, embedded within a self-produced matrix of extracellular polymeric substances (EPS). This matrix adheres to surfaces and protects the microorganisms from environmental stresses, disinfectants, and antibiotics.

The formation of biofilms is a dynamic process that can have profound negative effects on thermal transfer, health, and steel corrosion.

Negative Effects on Thermal Transfer

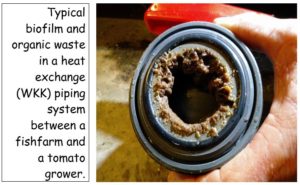

Biofilms act as thermal insulators due to their composition and structure. In systems where efficient heat exchange is crucial, such as in cooling towers and heat exchangers, the presence of a biofilm can significantly reduce thermal conductivity. This reduction in heat transfer efficiency can lead to higher energy consumption, increased operational costs, and the need for more frequent maintenance and cleaning. The biofilm effectively creates a barrier that slows down the transfer of heat between surfaces and fluids, making the systems less efficient and more costly to operate.

Negative Health Effects

Biofilms in water installations can harbor pathogenic microorganisms that pose serious health risks. Legionella pneumophila, the bacterium responsible for Legionnaires’ disease, can grow within biofilms and be released into the air through aerosols generated by cooling towers, showers, and faucets. Other pathogens that can live in biofilms include Pseudomonas aeruginosa, responsible for various infections, and Mycobacterium avium complex, which can cause respiratory and other infections. The protection offered by the biofilm matrix makes these microorganisms more resistant to disinfection, complicating efforts to eradicate them and posing ongoing health risks.

Negative Effects on Steel Corrosion

Biofilms can accelerate the corrosion process of steel and other materials used in water installations. This phenomenon, known as microbiologically influenced corrosion (MIC), involves microorganisms in the biofilm producing corrosive substances, such as acids and enzymes, that directly attack the metal surface or alter the local microenvironment in a way that promotes corrosion. MIC can lead to the rapid deterioration of infrastructure, causing leaks, failures, and the need for costly repairs or replacements. The economic impact of MIC is significant, affecting not only the immediate costs of addressing the corrosion but also the longevity and reliability of the systems involved.

Conclusion

The formation of biofilms in water installations poses significant challenges for thermal transfer efficiency, public health, and the integrity of materials. Managing biofilm formation requires a comprehensive approach, including regular monitoring, mechanical cleaning, chemical treatment, and, where possible, design considerations that minimize areas where biofilms can easily develop. Understanding the dynamics of biofilm formation and implementing effective control measures are essential for maintaining the efficiency, safety, and durability of water installations.

Biofilms are nutrient-rich layers (often slimy) and grow virtually everywhere and in almost any environment where there is a combination of :

- a liquid or moist environment

- nutrients

- a man-made or natural surface (the substrate)

In addition, optimal acidity and temperatures + stagnant water will even accelerate the growth.

For example, temperatures between 20 and 45°C already promote legionella growth while they proliferate best at temperatures between 32 and 35°C.

In particular, dead-legs or end pipes of (emergency drench) showers and sprinkler installations are vulnerable for this bacterial build-up.

Contrary to what many people think, even electropolished stainless steel surfaces can attract biofilm formation.

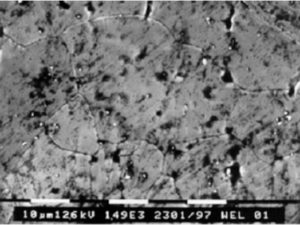

Picture Right : Stainless steel surface with pore contamination,A=1500x ( Source Dockweiler Nederland b.v. )

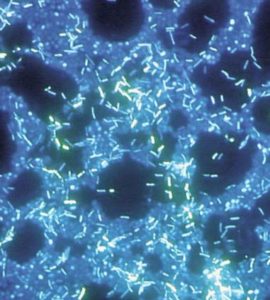

Picture left : Polymicrobic biofilm grown on a stainless steel surface in a laboratory potable water biofilm reactor for 14 days, then stained and examined by epifluorescence microscopy. (source CDC,2002)

Even desalinated, demineralized and UPW (Ultra Pure Water) are prone for biofilm formation due to the presence of oligotrophs. (organism that can live in an environment that offers very low levels of nutrients)

On this website we concentrate on the applications where bacteria and/or perseverant biofilm formation is not desired due to economic, functional, esthetic or health reasons. (causing undesired smell, disease, clogging, slime formation, algal bloom (like HAB’s), reduced heat transfer, etc…)

In essence, we remove the feeding ground of many micro-organisms and stop the binary fission (multiplication) of bacteria by causing vibration and stress in the liquid . In addition, resonant frequencies can impair the vital membranes of cells and vacuoles.

The result is a reduced CFU value and thus a more sterile environment where biofilms cannot accumulate.

In general, micro-organisms have the tendency to attach to surfaces and develop biofilms. These biofilms may occasionally loosen and attach themselves further in the system causing clogging and reduced flux.

A biofilm is an assemblage of surface-associated microbial cells that form an extracellular polymeric substance, named EPS-matrix.

Therefore, a biofilm consists of highly hydrated and immobilized cells that stick to a substratum.

The essential requirements for biofilm growth are the microbes themselves and a substrate.

For bacteria, the advantages of biofilm formation are numerous:

- protection (from antibiotics, disinfectants and dynamic environments).

- Intercellular communications within a biofilm and rapidly enabling temporal adaptation.

- the ability to survive in nutrient deficient conditions.

⚡ Microbes are microscopic single celled organisms and are present everywhere. They belong to the oldest lifeforms on earth and include (multi resistant) bacteria, fungi, yeasts and viruses. ⚡

Although many micro-organisms are beneficial (like in beer, yoghurt or cheese making), many are not desired in certain industries and under certain circumstances.

The negative implications of biofilm growth in the industry are enormous.

The mechanisms behind the attachments are Adhesion (cell-to-substrate attachment) and Cohesion (cell-to-cell attachment).

About 99% of the world’s bacteria population is found in the form of a biofilm. A minority remains free floating (planktonic state) in the liquid.

In drinking water systems it is since long known that at least 95% of the microbial growth is concentrated in the biofilm (see Windender, Flemming et al)

Examples of industries suffering from the negative effects of biofilms are:

Maritime, dairy, agriculture, food and beverage, water treatment systems, oil, pulp & paper, opticians, (dentistry) hospitals, (fishing) ponds, cooling towers, datacenters, hotels and public buildings, …

Examples of the detrimental effects from biofilm forming are:

Health issues, product spoilage, reduced production efficiency, corrosion, unpleasant odor, unsightliness, infections, sickness, pipe blockage and equipment failure, increased energy consumption, etc.…

The shipping and oil industry specifically have problems with Microbiologically Influenced Corrosion (MIC).

This can occur by the presence of sulphate-reducing bacteria (SRB that produce H2S) in pipes and reservoirs. The result is pipe blockage, souring of the oil and (microbial)corrosion.

Apart from SRB there are also Sulphur Oxidizing, Iron Oxidizing and Iron Reducing bacteria with their own detrimental characteristics.

See more: Biofilm contributes to corrosion

With low power ultrasound, we can eliminate biofilm growth and both remove and prevent scaling

With the use of effective-micro-organisms or probiotics we can consume or convert the biofilm into a less harmful or even useful substance.

Example in the field of bioremediation: remove contaminants such as rust, calcium carbonate (lime), oils and greases, nitrogen compounds, etc.

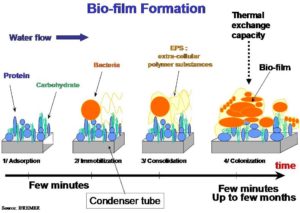

- Biofilm formation:

Biofilm formation is a dynamic process.

The first stages of biofilm formation are initially determined trough:

- free living bacteria being brought to the solid surface

- physical & chemisorption processes and hydrodynamic forces.

- extracellular organelles such as flagella, curli, fimbriae or pili

- outer membrane proteins (help to sense and interact with a given surface)

Source: Clemencedg IFREMER, 2010

These interactions can help cells overcome long-range repulsive forces along the surface. This process is critical in the formation of the biofilm structure and is influenced by the substrate surface (e.g. charge hydrophobicity etc.). It is at this stage that bacterial cells, usually held in Brownian motion, can be relatively easily removed through shear forces. Subsequently, once initial attachment has been made, flagellar arrest and the attached cells start to manufacture EPS. It is this process that promotes the transition of bacterial attachment from reversible to irreversible. The permanently attached cells are hard to detach owing to the EPS matrix. These micrometer communities grow into 3D structures as mature biofilms with EPS that acts as a ‘glue/adhesive’.

The biofilm is a tower-like (3D) inhomogeneous film.

For study purposes, they can be grown in a Calgary Biofilm Device (CBD) and made visual trough confocal laser scanning microscopy (CLSM)

One of the main biofilm components is water. Actually, researchers have been telling that the water would account for 80 % and more of biofilm.

Bacteria move toward materials’ surfaces by chemotaxis to obtain their nutrients there. However, it is not so easy for them to attach to the material surface because they must overcome some obstacles such as flow, surface conditions, coulomb forces, hydrophobicity, hydrophilicity, etc. Eventually, the bacteria attach to the materials. For a while, the bacteria continue the attachment and detachment process and finally, the number of bacteria begins to increase, as a result of the dominant attachment process. When the bacteria population reaches a certain value, they simultaneously excrete polysaccharides. The phenomenon is called quorum sensing. Originally, each microorganism (of bacteria) gives a certain signal protein out from its body along with other proteins. The amount of the signal protein called AI (auto inducer) tends to increase with the number of bacteria on a material’s surface. Therefore, the amount of AI reaches a certain value when the bacterial number also reaches a certain threshold value. When AI concentration exceeds a critical threshold value, it stimulates a certain part of the gene, which leads to the simultaneous excretion of polysaccharides. It is really just like a conversation among bacteria. They use chemical transmittance for the conversation. In this way, the polysaccharide is generated and bacteria begin to exist in the matrix of slimy polysaccharide on materials’ surfaces. The biofilm forms at this point.

We are realizing that bacteria within biofilms are the usual case and planktonic state bacteria should be considered an exception. Actually, some researchers pointed out that several tens of percentages for the phenotype could be changed from the planktonic state to the biofilm one. Usually, bacteria’s size is around 1 μm in the longitudinal direction. However, they tend to shrink to 60–80 % of the original length in biofilm. In this way, bacteria seem to change their existence, adjusting themselves to an energy-saving one, so that they get a chance to survive. The biofilm formed on materials’ surfaces incorporate many matters from the environment, such as mineral matters, organic matters, etc., as well as the interaction with substrates. In this way, the biofilm grows with the passage of time. The growth of biofilm depends on many factors such as temperature, other environmental conditions, the kind of substrates, etc. The flow is particularly very important. Actually, it is one of the most important factors to determine the biofilm structure and its characteristics.

The biofilm does not grow eternally. At a certain point, the collapse occurs inevitably. It seems that many factors might be involved in the breakdown of biofilm. These factors are still being investigated at this point. When the biofilm is broken, the biofilm bacteria are released into the environment again and their “dormant” state is changed to that of planktonic bacteria again. They move to seek

nutrients and find material surfaces to attach to and grow on. The process is repeated. Therefore, the biofilm can be considered a kind of reservoir for planktonic Bacteria. Many phenomena in materials science and engineering relate to biofilm formation and growth. For example, corrosion has a close relationship to biofilm. Microbiologically influenced corrosion has been a discipline during this half century and has a close relation with biofilm formation. The problem of scale growth on the walls of cooling pipes is also one of the serious problems in the materials science and engineering field.

Since the inner walls of cooling pipes provide some appropriate growing conditions, biofilm could form and develop there very easily.

As microfouling builds up on the material’s surface, it forms slime and scale, which impact and reduce a pipe’s ability for heat exchange. This leads to operational performance deterioration in the contaminated system. Biofilms are viewed as one of the most common form in which microorganisms exist naturally in nature. Bacteria are elementary, unicellular and are able to grow, divide, adapt and sense.

Several external environmental factors also influence the production of EPS for favorable microcolony formation like:

- Glucose

- Anaerobiosis

- high osmoregularity

- temperature increase and/or sunlight

- ethanol

- limitations in iron concentrations

- ,…

The research of recent years has revealed, however, that bacteria preferentially attach to a variety of surfaces, and that bacterial communities exhibit properties, behaviors and survival strategies that far exceed their capabilities as individual bacteria. For instance, microbial biofilms are naturally tolerant of antibiotic doses up to 1,000 times greater than doses that kill planktonic bacteria.

The formation of all kinds of biofilms cost the industry yearly billions of Euro’s due to:

- energy losses (heat exchangers or ship’s hull)

- equipment damage (leaks, clogging)

- product contamination and spoilage

- medical infections and disease. (health issues, antibiotic intolerance)

- maintenance costs (manhours and material costs)

- machinery downtime (operational costs)

- …

See also: https://www.alvimcleantech.com/cms/en/about-biofilm and Biofilm detections & monitoring | Maritech CV