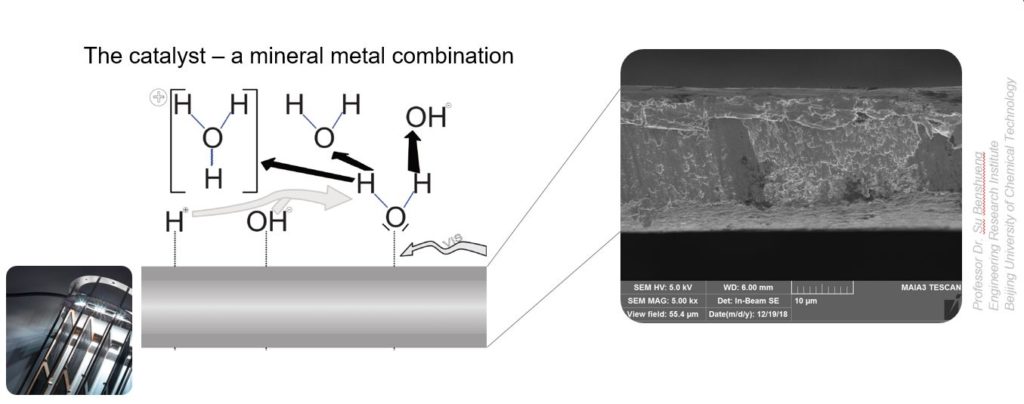

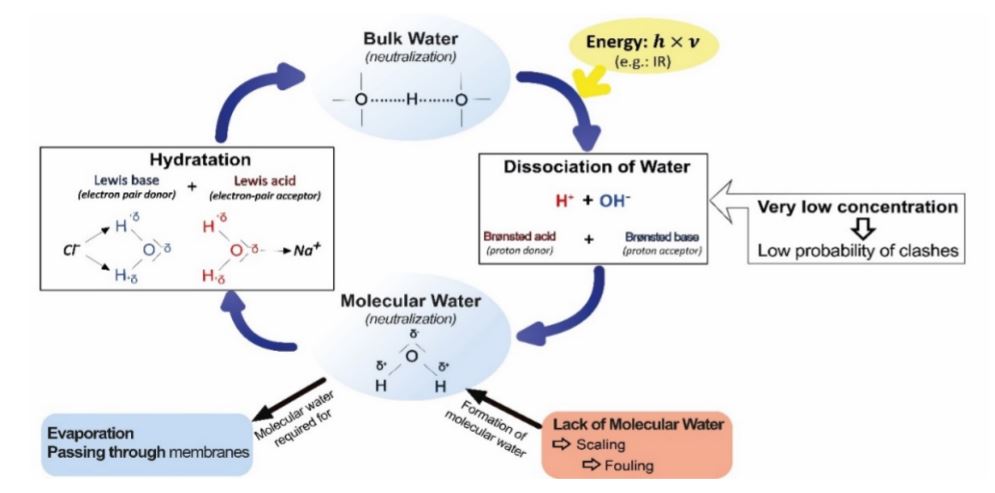

Working principle: The core element of the MOL®LIK-technology is a proprietary ultra- thin metal catalyst foil, made of nickel, chromium and iron. These catalysts are speeding up the formation of solvatation shells. The result is that more hydration shells are formed and therefore the equilibrium between bulkwater and molecular water is reached faster. The faster these shells are prepared, the less clusters are formed and the better flux is achieved. As a side effect, the risk of deposits formation and biofouling is greatly minimized.

These catalysts are speeding up the formation of solvatation shells. The result is that more hydration shells are formed and therefore the equilibrium between bulkwater and molecular water is reached faster. The faster these shells are prepared, the less clusters are formed and the better flux is achieved. As a side effect, the risk of deposits formation and biofouling is greatly minimized.

(source: Environmental Engineering and Management Journal)

Occasional interaction of low-energy visible light can additionally facilitate this process. The usage of this special catalyst technology results in a more efficient membranes process with optimized usage of chemicals.

Catalytic water treatment from MOL has been proven to be highly reliable, efficient & cost effective for power plants, refineries, RO-installations, domestic use and many other applications.

As a new application we are happy to announce that we can lengthen the lifespan of active carbon in filtration systems (=time before regeneration).

Case studies:

Cooling water treatment at KNG Rostock (GE)

Cooling water treatment at Proferro Belgium 2022(Eng)

How MOL improves your RO-performance

In the news 21/02/2025 : Max Planck Institute.

Contact us for studies and references relevant to your applications.

Youtube link : How it Works (Eng)