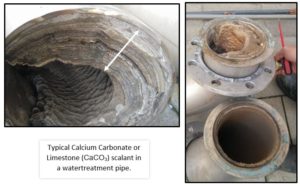

Calcium carbonate (CaCO₃) buildup in boilers and sanitary systems, commonly known as “scaling,” presents several significant challenges:

Reduced Heat Efficiency: In boilers, the buildup of scale on heating elements and interior surfaces acts as an insulator. This reduces the efficiency with which heat is transferred from the heating element to the water. Consequently, more energy is required to achieve the same level of heating, leading to higher energy consumption and costs.

Flow Restriction: In pipes and sanitary systems, scale buildup can narrow the diameter of the pipes, restricting the flow of water. This can lead to reduced water pressure and flow rate, which may require more powerful pumps to maintain water flow, further increasing energy usage and operational costs.

Increased Maintenance Costs: The presence of scale often necessitates more frequent maintenance and cleaning of affected equipment. Chemical descalers, mechanical scrubbing, or even replacement of heavily scaled parts may be required, all of which contribute to increased maintenance costs.

Equipment Damage and Failure: Over time, scaling can cause significant physical damage to components. In boilers, for example, excessive scale buildup can lead to overheating and failure of the boiler tubes. In sanitary systems, scaling can lead to corrosion beneath the scale layers, potentially causing leaks and failures in the system.

Decreased Lifespan of Equipment: The overall effect of scaling is a decreased operational lifespan of both boilers and plumbing systems. Frequent overheating, increased mechanical wear, and corrosion can all prematurely age these systems.

Water Quality Issues: In sanitary systems, scale can harbor bacteria and other pathogens, potentially affecting the quality of the water supply and posing health risks.

By choosing the right physical water treatment method we can prevent and eliminate (over time) existing Limescale in boilers and piping systems.

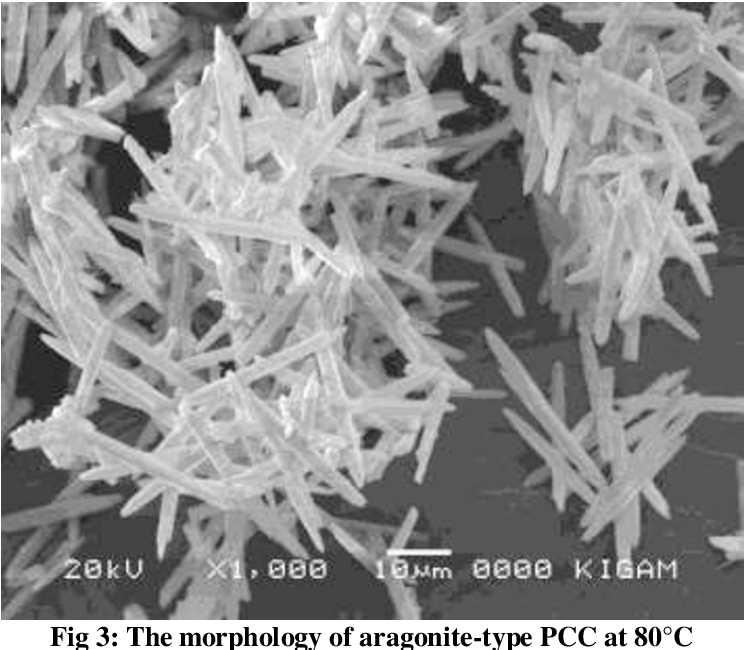

We use only innovative and physical water treatment techniques that increase solubility and converts CaCO₃ to a less adhesive crystalline form, specifically aragonite, instead of the more common and problematic calcite.

We use no magnets or electromagnetic technologies.

Workings:

- As water flows through the treatment device, the calcium ions (Ca2+) and carbonate ions (CO₃2+) in the water are influenced by the ultrasound, biosignal and/or electron transfer due to the specific surface of the catalytic media.

- This interaction alters the nucleation dynamics of the calcium carbonate and helps the creation of hydration shells, promoting the solubility and formation of aragonite over calcite. Aragonite has a needle-like structure which is less likely to form hard, adherent scales compared to the more cubical structure of calcite. It does also not adhere as strongly to surfaces, reduces buildup and flushes out of the system more easily.

Continuous Operation:

- For the best results, these treatment systems need to operate continuously. This ensures that all the water entering the system is treated, maintaining the preventive effect against scaling.