Join us on 10 – 11 – 12 June 2025 at RAI Amsterdam for the #1 horticulture technology event!

Industry professionals from all over the world come together to connect, network, share knowledge and do business.

Sustainable Solutions against Biofilm and Reduction of the Microbial Load

With over ten years of experience in physical water treatment, we would like to offer you a sustainable alternative for tackling biofilm and microbiological issues in water systems – without or with significantly reduced use of chemical products.

Our approach is based on a combination of innovative technologies that allow us to address biofilm both preventively and curatively, while optionally also enriching the system with additional oxygen.

By controlling biofilm, we indirectly achieve a reduction in the microbial load (CFU or germ count) of the system. “Indirectly” means that there is no biocidal action, and therefore no restrictions in relation to biocide legislation. (BPR, Regulation (EU) 528/2012)

Additionally, by introducing microbubbles and dissolved oxygen (DO), we increase the oxidation potential and the diffusion rate of dissolved substances.

Some of the proven techniques we can apply include:

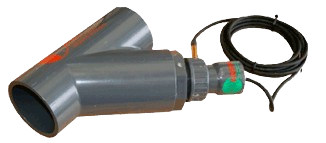

- Low-power Ultrasonic Technology

A system that creates a range of specific ultrasound waves that have clearly defined functions in the water treatment.

This technology destroys algae, generates microbubbles (=cleaning effect), and creates a stress environment for microorganisms, making it harder for them to proliferate.

– Power consumption: only 40 W per system

– Easy installation in-line or in tanks or basins

– No maintenance required

- Solid-State Heterogeneous Catalysts

These fixed metallic catalysts that improve the solubility of the water, generate microbubbles, and prevent scale and biofilm formation. We also see a significant benefit for flocculation and coagulation.

– No power consumption (unless the photocatalytic option is added)

– Maintenance-free when combined with ultrasound

– Easy installation in-line or submerged in a pressureless tank

- Biosignal Technology

These are Al-Si rings with a crystalline structure that emit subtle subatomic signals, this technology influences attraction and repulsion of ions, leading to the breakdown and prevention of biofilm and scale. It also increases the soluble effect of water.

– No power consumption

– Completely maintenance-free

– Easy to install externally, without dismantling pipes and without stopping the production

- Ultrafine Microbubbles

This technique enriches the water with dissolved oxygen (DO) and enhances oxidation processes (oxygen availability). It also naturally forms hydroxyl radicals (•OH) and superoxide (O₂•⁻), which reduce the need for biocides. Furthermore, the microbubbles have a cleaning effect on pipe walls and tanks.

🔍 Comparison of Technologies

Technology | Advantages | Power/Maintenance | Ease of Installation |

Ultrasonic Technology | – Algae control- Microbubbles with cleaning effect- Inhibits microbial growth | 40 W / Maintenance-free | Easy to place in basins or in-line with pipework |

Heterogeneous Catalyst | – Prevents biofilm- Increases gas solubility in water | No power / Maintenance-free (with ultrasound) | Inline or immersion placement possible |

Biosignal Technology | – Removes biofilm and scale- Improves mixing of dissolved substances | No power / No maintenance | Very easy, external mounting on pipes |

Ultrafine Microbubbles | – Increased DO- Enhanced oxidation and mixing- Reduces biocide use | No power / No maintenance | Very easy, external mounting on pipes |

We specialize in delivering the best available chemical-free solutions for:

- Cleaning of wet surfaces, elimination of biofouling and reduction of microbiology in:

- piping systems

- above-and underground storage tanks

- cooling towers

- heat exchangers

- Fighting (toxic)algae blooms in ponds and recreational waterbodies

- Reducing corrosion and biofouling on submerged marine structures.

- Aerating water masses to increase DO to fight aquatic hypoxia and to improve waste water recycling installations trough AOPs

- Improving flux and MTBF in RO’s and active coal filtration systems.

Our emphasis is :

- on the use of environmental acceptable techniques, methods and products

- to avoid dismantling and installation downtime (optimize MTBF)

- to act, if possible, both preventive and curative

- to reduce or completely avoid the use of harmful chemicals like biocides, descalants or inhibitors

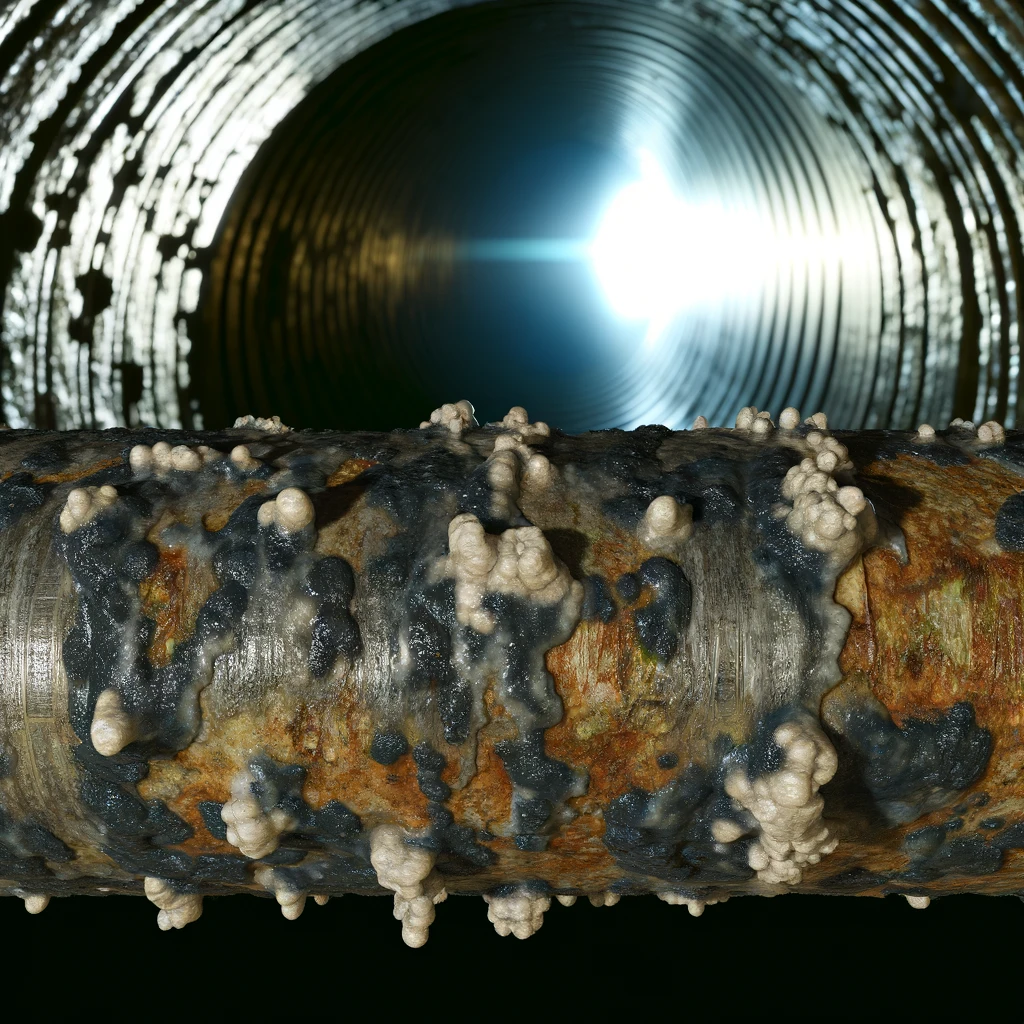

What general contamination usually comes down to is the formation of dynamic communities of surface-attached multi-species forming a “biofilm”.

All liquids contain free floating (planktonic) micro-organisms and have the tendency to initiate bio-fouling on their contact surfaces. What follows is the formation of a biofilm that again will attract and accumulate more of contaminants.

In general, biofouling (surface contamination) is removed manually or with (sometimes harmful) surface re-acting agents such as disinfectants, biocides or aggressive additives.

We made it our task to select and offer safer and more environmentally friendly methods like ultrasound, catalysts (NOA’s), biosignal technology, among others.

Our methods have the advantage of being :

- able to clean thoroughly and even into cracks and pores. They also bypass the survival strategies of certain bacteria (the so called habituation and sensory adaptation).

- used as CIP (Cleaning In Place) thus eliminating downtime and disassembling of installations.

Other advantages :

Other advantages :

- no (or very low) power consumption

- the use of chemicals can be reduced or sometimes completely eliminated

- systems can be custom build for a variety of applications

- works preventive and in some cases also curative

- no (or very low) maintenance required

- in most cases, the organoleptic properties of the treated liquid are not changed (like texture, color and taste), making the treatment useful for the food-and beverage industries.

“Humans, animals and their environment request a change in mentality with regards to the use of chemicals and biocides”

Biofilms are nutrient-rich layers (often slimy) and grow virtually everywhere and in almost any environment where there is a combination of :

- a liquid or moist environment

- nutrients

- a man-made or natural surface (the substrate)

In addition, optimal acidity and temperatures + stagnant water will even accelerate the growth.

For example, temperatures between 20 and 45°C already promote legionella growth while they proliferate best at temperatures between 32 and 35°C.

In particular, dead-legs or end pipes are vulnerable for this bacterial build-up. Even desalinated, demineralized and UPW (Ultra Pure Water) can contribute to biofilm formation due to the presence of oligotrophs. (organism that can live in an environment that offers very low levels of nutrients)

On this website we concentrate on the applications where bacteria and/or perseverant biofilm formation is not desired due to economic, functional, esthetic or health reasons. (causing undesired smell, clogging, slime formation, toxic algal blooms, reduced heat transfer, etc…)

In essence, we prevent or remove the feeding ground of many micro-organisms with physical water treatment technologies.

The result is less scaling and a reduced CFU value, meaning a more clean and sterile environment.

We offer both off-the-shelf products as well as customized and scalable systems whereby the efficiency can be measured to optimize the results needed.

Maritech offers a wide range of innovative products and solutions designed with your needs in mind.

Usage ranges from traditional domestic, recreational and industrial applications to more pioneering and newly emerging fields.

Join us on 10 – 11 – 12 June 2025 at RAI Amsterdam